Building my first PCB with my Dad…

My Dad's Son

Way back in the mid-70’s when I was just a very young boy (8 or 9 at the time), I was a rabid reader of Popular Electronics. For those of you who don’t know what that was, it was the Circuit Cellar of its day, but more geared towards analog. They did do a lot of digital projects as well. I remember building circuits with the yellow punch boards and posts, wiring the components to the posts and then using jumper wire between the posts.

This was a great time for me, my father was an Electrical Engineer and we used to work on these together and he would take the time to help explain how the circuits worked when I was confused with what was written in the magazine.

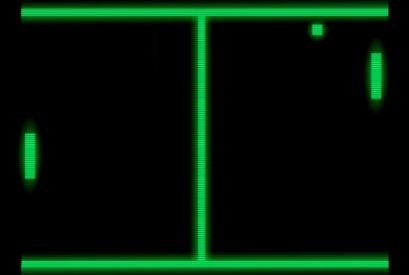

One day, I came across the most AMAZING project in an old copy of the magazine! It was the design of a pair of “Digital Dice.” This was something that I HAD to have! Imagine, no longer did you need to actually pick up a pair of dice and roll them across the board and having them fall onto the ground. You could simply push a button and when you released it, your dice roll was displayed for you!

I knew up front that I had to do this right, with a PCB (since it used 110V!) and it needed to be mounted in a nice box. Popular Electronics would even give you the PCB layout (Single Sided!) and you could even buy the PCB (or all parts) via mail order through an address in the article. However, my Dad had other ideas…

Soon after I expressed my desire to build this device, my dad brought me into his work and into their PCB room to manufacture the PCB with him. This process was NOTHING like it is done today. There was an entire white wall of the room that you would lay out the PCB on using pre-made black cutouts, sticking them to the wall to lay out the PCB. Of course, this layout was not done in 1-1 scale. I remember the PCB was only a few inches on each side, but they layout we did was a couple of feet across. There was a faint grid on the wall you could use to align the cutouts for DIP packages and such. This process was very easy for this project since we could use the layout in the magazine as a guide. To this day I can’t imagine doing this for new designs since all routing was done by hand. Once the layout was done, we used a black & white camera to take a picture of the wall.

After we had developed the film and had a negative, we used an enlarger to focus the image at the proper scale on a piece of pre-coated copper PCB to set the photo-resist. Then it was off to the etch tank to eat away the unnecessary copper. At that point, my dad handed me a piece of steel wool to scrub off the tarnish/resist on the remaining copper and then we dunked it into the tinning bath. Finally, at the end of all this I had my PCB!

I still to this day remember going with my dad to buy the rest of the parts and then sitting in our living room soldering them all to the board. My dad helped me with drilling out the case and assembling the entire unit. Eventually we got the device working and I used it for several years, until Dungeons and Dragons came along and needed dice that were more than 6 sided!

While I have made many PCB’s since then, that first PCB is still my favorite one.

I recently found the magazine/project on line and you can see it here: http://www.swtpc.com/mholley/PopularElectronics/Sep1967/PE_Sep1967.htm

- Shared October 11, 2012